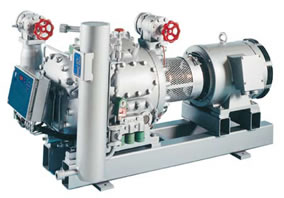

TCMO/TSMC Two-Stage Reciprocating Compressor

TCMO/TSMC Two-Stage Reciprocating Compressor

In all low-temperature refrigeration installations, two-stage reciprocating compressors are an economical operating alternative to single-stage screw compressors.

JWI TCMO/TSMC two-stage reciprocating compressors are therefore ideal for medium-size industrial and marine refrigeration installations. They are the most reliable and economical option for a range of heavy-duty applications on this particular scale, where an extended service life is required.

The TCMO/TSMC range includes eight two-stage models that provide capacities between 175 and 1018 m3/h low pressure swept volume at maximum speed.

Compatible and upgradable

The JWI TCMO/TSMC design is future-compatible because ongoing changes and improvements are designed so that they can also be implemented on earlier TCMO/TSMC models. This makes it easy to upgrade and retrofit older compressors to the most recent specifications.

TCMO 28 direct-coupled unit with shell-and-tube intermediate cooler

Significant advantages

The advantages of the JWI TCMO/TSMC compressor design include

- High coefficient of performance (COP), with excellent part-load characteristics.

- Excellent accessibility – including simple-to-clean water covers and externally accessible oil pump/filter (TSMC 100 only) – and limited spare parts requirements.

- Any necessary repairs can normally be undertaken without having to remove the compressor.

- Chromium piston rings, gas-dampened discharge valves and hardened cylinder liner surfaces.

- Spring-loaded safety heads, balanced refrigerant-tight shaft seal, asbestos-free gaskets and an internal bypass valve to prevent excessive pressure.

Customer benefits

For the customer, the benefits of the JWI TCMO/TSMC compressor design include

- Lower power consumption, especially when operating at part load. This greatly reduces operating costs.

- Easy maintenance, resulting in low service costs and minimal downtime.

- All repairs can be carried out on site at the customer’s own premises, reducing both repair costs and downtime.

- Extended service life for all moving parts.

- The special design ensures low noise and low vibration levels, with safe, environmentally responsible operation.

Standard equipment

JWI TCMO/TSMC compressors are supplied with the following equipment as standard

- compressor block with oil pump and oil filter

- solenoid valves for capacity control

- suction and discharge stop valves

- safety valve

- oil-charging valve

- suction filter

- oil-level sight glass

- electric immersion heater in crankcase

- evacuation valve

- pre-lubrication valve.

Optional equipment

A wide range of optional equipment is also available for JWI TCMO/TSMC compressors. This includes

- gauges, thermometers and temperature/pressure control switches

- Sabroe Unisab IIl microprocessor control with temperature/pressure sensors

- extended one-cylinder capacity control or standard capacity control with full unloading (TSMC 100 only)

- oil level regulator for parallel systems

- explosion-proof equipment

- base frame with coupling and guard for direct-drive unit

- base frame with pulleys, belts and guard for V-belt drive unit

- motors

- oil separators with solenoid valve and TLT valve (TSMC 100 only) for oil return

- oil charging pump

- vibration dampers and foundation bolts

- tool sets

- sets of genuine Sabroe spare parts.

Compressor and oil cooling

Depending on specific refrigerant and operating conditions, it can be necessary to supplement basic air convection cooling with one of the following options to make sure that the compressor and the lubricating oil are cooled efficiently are cooled efficiently

- water-cooled head covers

- water-cooled side covers for oil cooling

- refrigerant-based oil cooling

- thermo-pump system (for use with R717 only).

Intermediate cooling systems

The two-stage compressors are available for connection to a common intermediate cooler in plants with multiple two-stage compressors. Alternatively, the following intermediate cooling systems are available in built-on form, as optional equipment

- injection interstage gas cooling without liquid subcooling

- injection interstage gas cooling with liquid subcooling in a shell-and-tube heat exchanger

- closed flash interstage cooling in a shell-and-coil intermediate cooler with liquid subcooling in the coil.

Technical Data